DW30

Download brochure

Production of locknuts and moulded locking parts by part-ovalisation of the nut body.

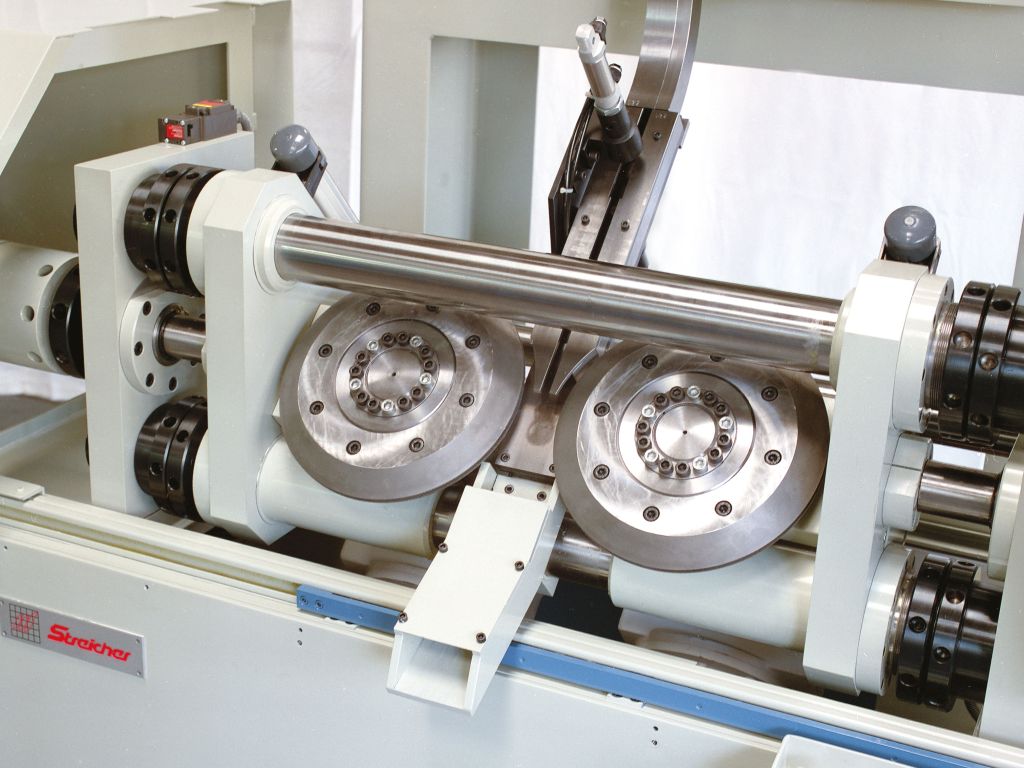

Two rotating rollers, situated opposite to each other, are the central feature of the machine.

The distance between the rollers is less than the nut that is being fed through.

This causes the nut to be slightly deformed and a change in thread geometry.

The distance between the rollers is adjustable; thus all standard nut sizes can be deformed by means of just one machine type.